Manufacturing strength

The company has advanced production and manufacturing concept, the quality inspection and experiment center approved by the host supporting unit, and maintains the controllability of high-precision and high-quality bearings during the whole process of product feeding production and logistics transportation.

Production design concept advancing with the times

Production design concept advancing with the timesThe company is a 20-year experience of R & D, design and manufacturing as one of the automotive bearing manufacturing enterprises, in the field of auto parts has many years of host matching and after-sales market experience.

High end intelligent production and processing equipment

High end intelligent production and processing equipmentThe MES system with digital control technology is used to facilitate the overall process control of products and provide a solid hardware guarantee for customers to manufacture high-precision products.

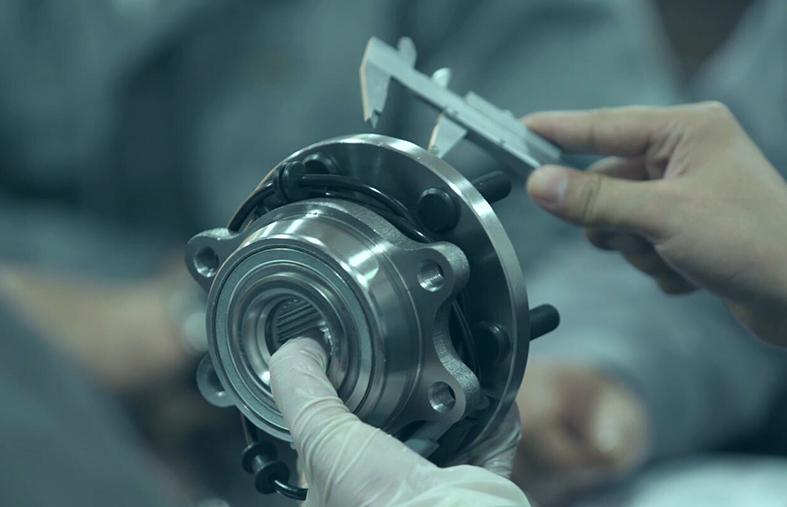

Main engine supporting approved quality inspection equipment

Main engine supporting approved quality inspection equipmentAll kinds of high-precision testing instruments directly serve the production site, monitor the production process in real time, and ensure the consistency and stability of product size, shape and performance.

High end automatic assembly and wiring equipment

High end automatic assembly and wiring equipmentAutomatic and intelligent transformation of production assembly line. It can not only greatly reduce the human errors, but also ensure the quality and efficiency of product assembly.

Host supporting approved Experiment Center

Host supporting approved Experiment CenterPerfect experimental equipment not only meets the requirements of TS16949, but also helps to better meet the requirements of automobile manufacturers and automobile customers as well as the requirements of sample approval in the early stage and become a high-quality supplier.

Efficient and stable logistics transportation system

Efficient and stable logistics transportation systemThe professional logistics system can ensure the high-end quality in the process of goods transportation, protect the personal information of customers and arrive at customers' warehouse on time.